CAPE Cable Glands with Constant Force Grounding

Simplify Design, Procurement and Installations

Design

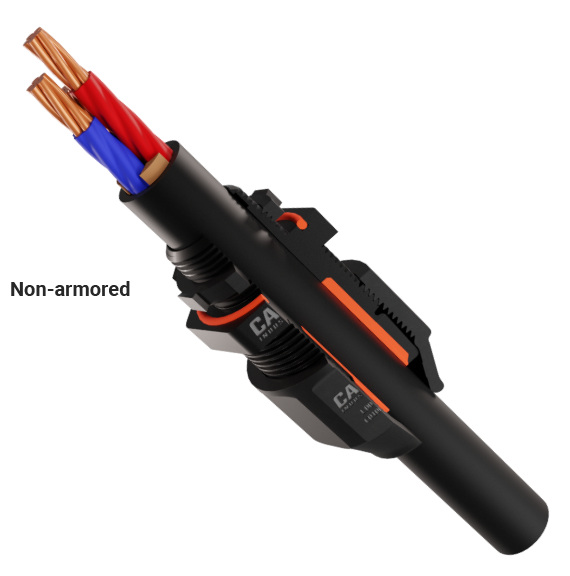

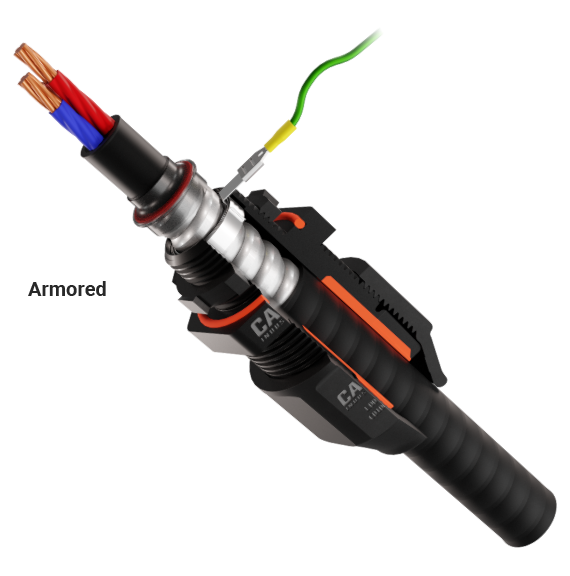

Unlike other cable glands that have multiple material, design and size complexities varying by application, CAPE simplifies the design and material to deliver a single solution to perform in both ordinary and hazardous applications.

Procurement

Installations

CAPE cable glands have the beneficial combination of the industry’s widest cable diameter range within the least number of SKUs, eliminating time wasted by changing sizes should a cable in a different size arrive on the project site.

Lighten the Load

Metal cable glands are heavy. CAPE’s high-tech polymer materials are not, which reduces weight on all applications. If it floats or flies, this means more payload capacity and less fuel consumption. For all projects, lighter weight means decreased shipping and logistic costs.

Lower Costs Across the Board

CAPE’s simple, yet high-performance, cable glands deliver accurate and time-efficient installs with less risk of lost or removed components that void certified installations. With only 4 sizes to connect cables ranging from 0.125 inches to 1.25 inches O.D., CAPE cable glands provide the most flexibility for designers and installers, and the most time and cost savings for project owners and maintenance teams.

Excellent Resistance Against

- Water

- Corrosion

- UV/Sunlight

- Impacts

- Abrasion

- Hydrocarbons

- Acids

- Alkalis

- Mildew

- Aging

“Performance like metal, with the flexibility, weight and cost benefits of polymers.”

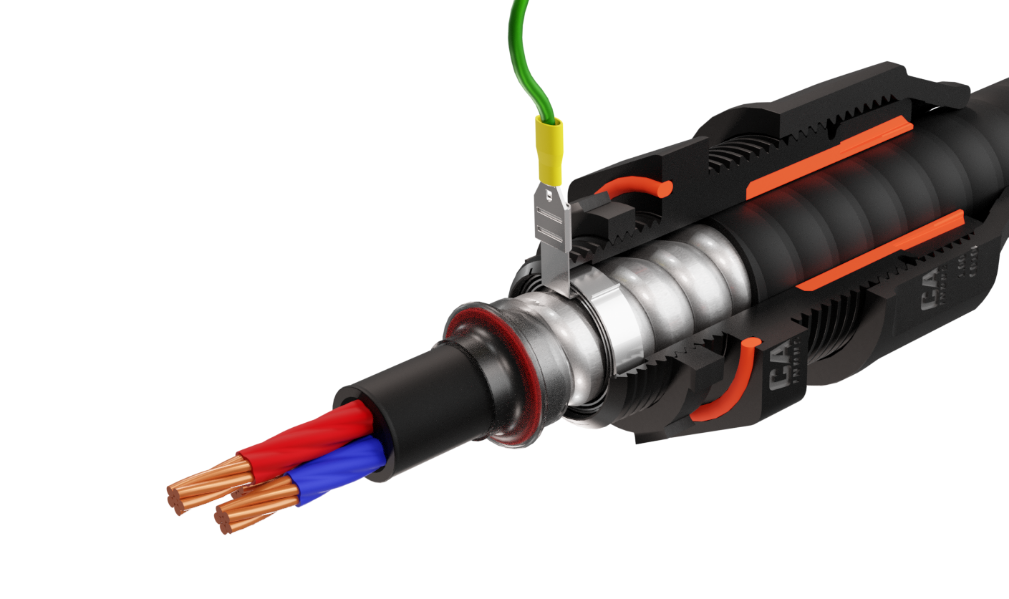

One-and-Done Solution Simplifies Complex Connections

4 NPT sizes work for cable sizes ranging from 0.125 inches to 1.25 inches. Metric threads coming soon!

- Significantly reduces number of SKUs and inventory requirements

- Simplifies design and specification

- Speeds installation through standardization and fewer parts

Pending global certifications

CAPE Cable Glands Technical Data

- -60o C to +80 o C (-76F to 176F)

- Non-corrosive

- Suitable for NEMA enclosures 3, 4 & 4X

- Chemical and hydrocarbon resistant

- Resistant to impact, torque and UV

- Designed and tested to replace stainless steel, brass and aluminum