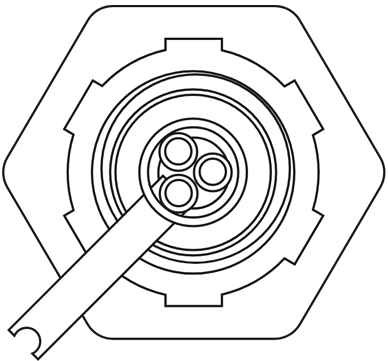

Introducing the CAPE Cable Gland with Constant Force Grounding

Lower Costs

Simplify Design, Procurement and Installations

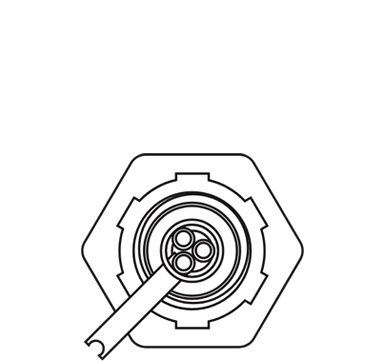

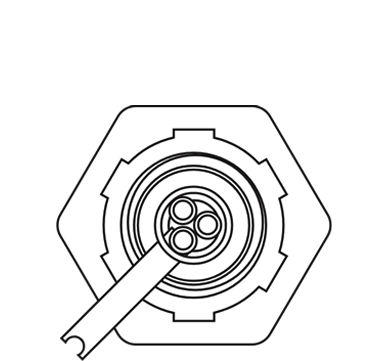

Unlike other cable glands that have multiple material, design and size complexities varying by application, CAPE simplifies the design and material to deliver a single solution to perform in both ordinary and extreme applications.

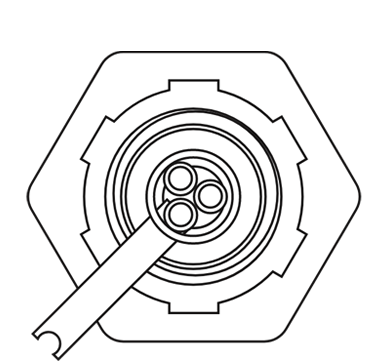

CAPE’s simple, yet high-performance, cable glands deliver accurate and time-efficient installs with less risk of lost components that void certified installations. With only 4 sizes to connect cables ranging from 0.125 inches to 1.25 inches O.D. – CAPE cable glands provide the most flexibility for designers and installers.

CAPE cable glands have the industry’s widest cable diameter range, eliminating time wasted by changing sizes should a cable in a different size arrive on the project site.

Lighten the Load

CAPE Cable Glands Technical Data

- -60o C to +80 o C (-76F to 176F)

- Non-corrosive

- Suitable for NEMA enclosures 3, 4 & 4X

- Chemical and hydrocarbon resistant

- Resistant to impact, torque and UV

- Designed and tested to replace stainless steel, brass and aluminum

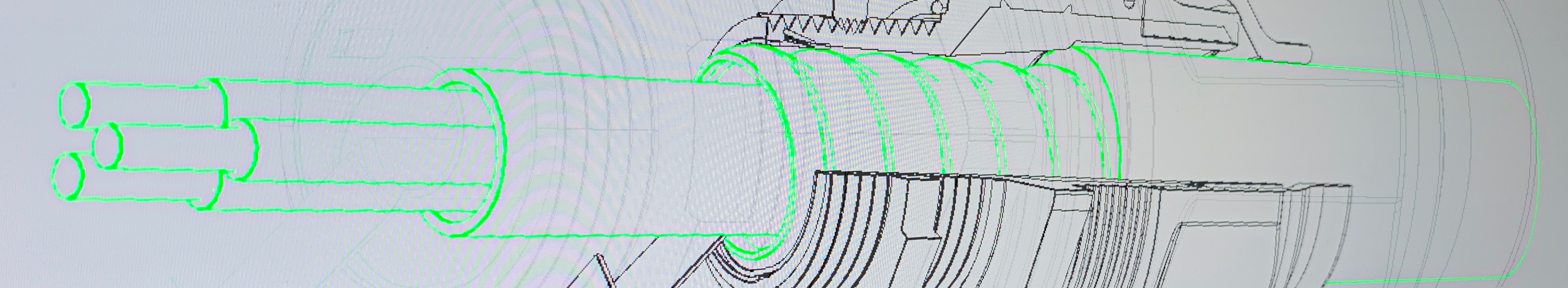

One-and-Done Technology

.5 inch

.75 inch

1.00 inch

1.25 inch

CAPE cable glands are currently pending third-party globally certification* for heavy industrial electric connections.

Det Norske Veritas (Norway) and Germanischer Lloyd (Germany)

Underwriter Laboratories

The Canadian Standards Association (CSA)

ATEX certified electrical equipment

American Bureau of Shipping

International Electrotechnical Commission

International Electrotechnical Commission Explosive

- IEC 60079-0:2017 - Explosive atmospheres - Part 0: Equipment - General requirement

- EN 60079-0:2018 - Explosive atmospheres - Part 0: Equipment - General requirements

- IEC 60079-7:2015/AMD1:2017 - Explosive atmospheres - Part 7: Equipment protection by increased safety "e"

- EN IEC 60079-7:2015+A1:2018 - Explosive atmospheres - Part 7: Equipment protection by increased safety "e"

- IEC 60079-31:2013 - Explosive atmospheres - Part 31: Equipment dust ignition protection by enclosure "t"

- EN 60079-31:2014 - Explosive atmospheres - Part 31: Equipment dust ignition protection by enclosure "t"

cLCus, cCSAus

- CAN/CSA-C22.2 No. 60079-0:15 - Explosive atmospheres - Part 0: Equipment - General requirement

- CAN/CSA-C22.2 No. 60079-7:16 - Explosive atmospheres - Part 0: Equipment - General requirement

- CAN/CSA-C22.2 NO. 60079-31:15 - Explosive atmospheres - Part 31: Equipment dust ignition protection by enclosure "t"

- UL 60079-0 (Ed. 6) - Explosive atmospheres - Part 0: Equipment - General requirement

- UL 60079-7 (Ed. 5) - Explosive atmospheres - Part 7: Equipment protection by increased safety "e”

- UL 60079-31 (Ed. 2) - Explosive atmospheres - Part 31: Equipment dust ignition protection by enclosure "t"

- UL 514B (Ed.6) / CSA-C22.2 No. 18.3-12 - Conduit, Tubing, and Cable Fittings

- C22.2 NO. 94.2-15 Enclosures for electrical equipment, environmental considerations (Tri-national standard withNMX-J-235/2-ANCE-2015 and UL 50E)

The Industrial (Cable Gland) Revolution

Finally, a cable gland that holds up to the most extreme industrial environments at a significant cost savings compared to traditional metal cable glands.

Simplify on-site installation with CAPE cable glands and our unique range for cable diameters with fewer moving parts.

Lighten the load on everything that floats or flies to create additional payload capacity, reduce fuel consumption and save on shipping and freight costs.